Introduction

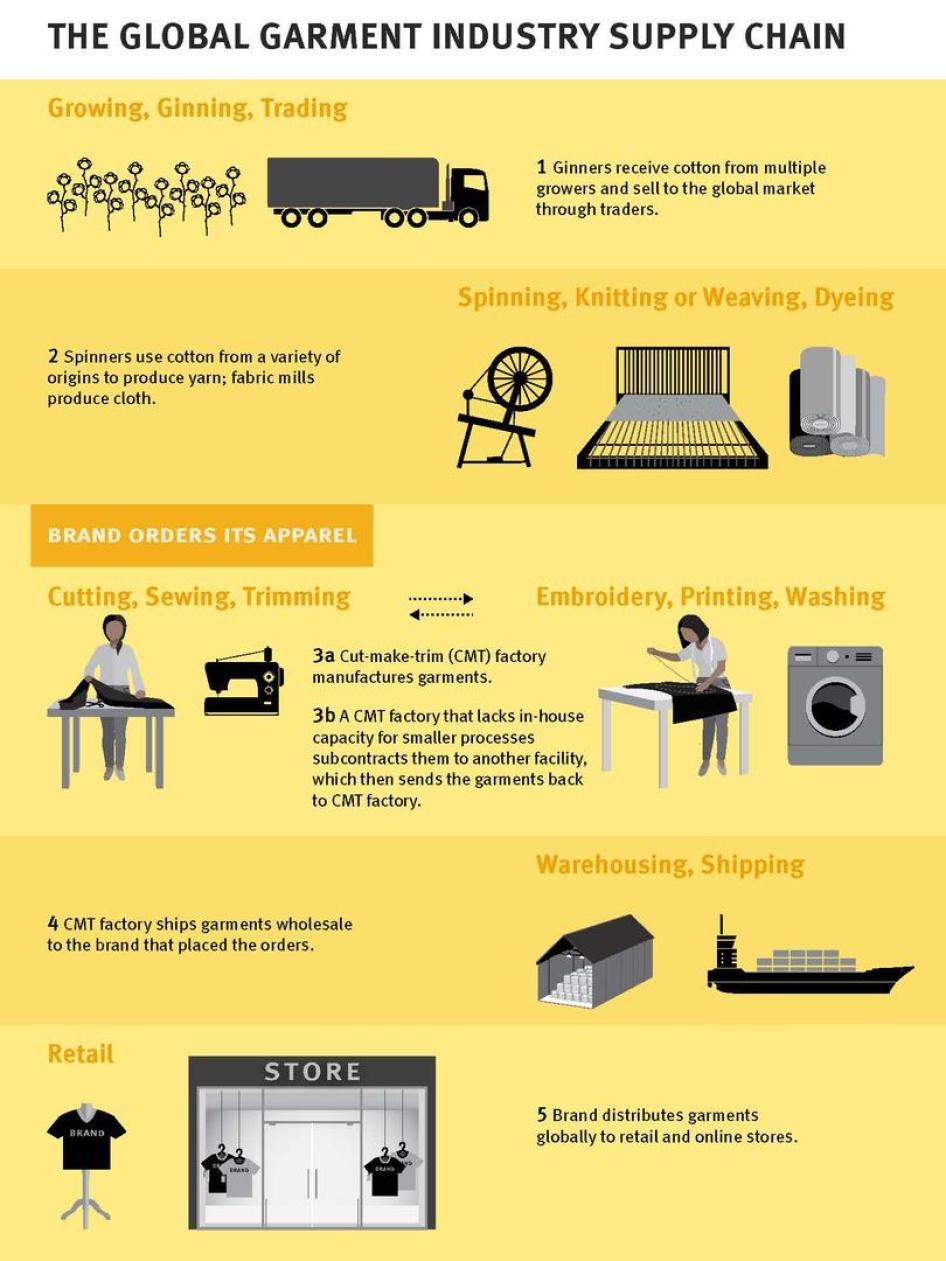

Transparency about supply chains in the garment and footwear industry is a rapidly growing trend. The complex network of global suppliers that apparel and footwear companies use to produce their goods is much less opaque than only a few years ago. Knowing factory details enables workers, labor organizations, human rights groups, and others to swiftly alert apparel company representatives to labor abuses in those factories, giving companies an opportunity to intervene—sooner rather than later— to stop and rectify abuses. It also facilitates brand collaboration and collective action to stop, prevent, mitigate, and to provide a remedy for labor abuses.

In 2016, nine human rights and labor rights organizations, together with global unions, formed a coalition to improve transparency in garment and footwear supply chains.[1] The coalition reached out to more than 70 companies with own-brand label products, urging them to align their supply chain disclosure practices with the “Transparency Pledge” standard and advance industry good practice.[2] The Transparency Pledge asked companies to publish on their websites a list of the names, addresses, and other details of at least the factories involved in assembling, embellishing, and finishing their goods (called tier-1 factories).[3]

In the two years since the coalition’s first report in 2017, there has been a significant increase in the number of companies that have published the details of their tier-1 supplier factories. The 2019 Fashion Transparency Index (FTI)—coming 14 years after the first company publicly disclosed its supplier factories list—shows that 35 percent of the 200 brands surveyed have published their tier-1 factory lists.[4] The percentage of brands publicly disclosing has more than tripled from the 12.5 percent of the 40 brands surveyed in the 2016 FTI that reported doing so at that time (about 45 percent of the brands surveyed in 2016 eventually publicly disclosed their supplier factories list). This discernible shift toward publicly disclosing supply chain data signals greater transparency as the direction in which companies are moving.

Consumer demand for brand transparency is also growing. Recent consumer surveys show that they have consistently demanded greater transparency[5] and that brand transparency builds consumer trust.[6]

Accelerating the pace at which companies adopt supply chain transparency is critical to making it an industry norm. Some apparel companies are leading the way among their industry peers and have innovated and moved beyond publishing only the details of their tier-1 supplier factories.[7] But many others lag behind, questioning the utility of transparency even though it has long been recognized as industry good practice, and resisting the publication of factory-level information. Apparel companies that are unwilling to at least publish the names, addresses, and other basic details about their supplier factories are failing to adopt key features of effective human rights due diligence.

As part of its efforts to raise the industry bar on transparency, the coalition continued to engage with many companies included in the 2017 report. Additionally, the coalition assessed the transparency practices of key Responsible Business Initiatives (RBIs) in the industry, company-backed efforts to promote more ethical practices among their corporate members.[8] Given the growing significance of online retail, the coalition wrote to two large online retailers—Amazon and Zalando—in 2018 (and had previously reached out to online retailer ASOS in 2016). The coalition urged them to publish their own-brand supplier factories lists aligned with the Transparency Pledge.

Building on our previous efforts, this report takes stock of supply chain transparency as of late 2019, updates information from the 2017 report, provides an overview of positive new developments in the industry, and makes additional recommendations aimed at improving apparel companies’ due diligence practices on human rights.

In summary, we call upon all companies to commit to and implement the Transparency Pledge in 2020 by disclosing names, addresses, and other details of supplier factories. We urge all Responsible Business Initiatives to bridge the transparency gap among corporate members, regardless of size or business model, and exert leadership by making supply chain transparency a condition of membership. And we urge all governments to enact laws governing companies’ mandatory due diligence of human rights responsibilities in their global supply chains, integrating supply chain transparency requirements.

Role of Responsible Business Initiatives and Transparency

Platforms that seek to drive responsible business conduct among their corporate members should be changemakers. Typically, such platforms are business associations that promote ethical trade or multi-stakeholder initiatives (MSIs) whose members include companies, nongovernmental organizations, and, in some cases, trade union organizations.[9]

In the apparel industry, there are at least seven widely known company-backed RBIs that profess to guide and encourage their corporate members to adopt stronger and deeper ethical behavior—amfori (formerly Business Social Compliance Initiative or BSCI); the Dutch Agreement on Sustainable Garments and Textiles (AGT); the Fair Labor Association (FLA); the Fair Wear Foundation (FWF); the German Partnership for Sustainable Textiles (PST); the Sustainable Apparel Coalition (SAC); and the UK Ethical Trading Initiative (ETI). Each of these initiatives is comprised of dozens of apparel and footwear companies, at times with overlapping memberships.

Often their best known corporate members take the lead among apparel brands and retailers on supply chain transparency (see Annex I online).[10] Many of these companies are publishing the names and addresses of their supplier factories; some are aligned with the Transparency Pledge standard; and some have supply chain disclosure practices that go beyond the pledge standard.[11] While responding to demands by college students and universities, consumers, civil society organizations, and ethical investors, companies that have thus far led on supply chain transparency have done so without waiting for an institutional decision by RBIs requiring such transparency.

Despite belonging to the same RBIs as those companies that publish information about their supply chain, many corporate members do not publish any information on their supplier factories, driving down the levels of supply chain transparency within these initiatives.[12] These companies cite the absence of an RBI policy requiring supply chain transparency as justification for not moving forward towards public disclosure, while failing to acknowledge that as the RBIs’ principal funders and significant participants in their governance, these companies, themselves, actually play a decisive role in determining RBI policies.[13]

As a result, such initiatives have not only had a transparency gap within their membership—some leaders and some lagging behind—but they may also be complicit in maintaining the status quo in the industry when they do not mandate public disclosure of lists of supplier factories by all their members.

RBIs should not only bridge this transparency gap among their corporate members; they should also play a leadership role by making supply chain transparency a condition of membership. While transparency has many different elements, the basics of supply chain transparency—that is, publishing the names, addresses, and other details of supplier factories—is a critically important place to start, since it is central to conducting effective due diligence on compliance with human rights responsibilities in accordance with the United Nations Guiding Principles on Business and Human Rights.[14]

In June 2018, the coalition wrote to and began engaging with the seven RBIs on their policies and actions driving their corporate members’ supply chain transparency.[15] Prior to the engagement by the coalition, none of the seven RBIs had firmly linked the transparency of individual corporate members’ supply chains to their membership requirements, or even to the level of their membership. The coalition urged these RBIs to require as a condition of membership that companies individually publicly disclose information about their supply chains by January 2020, at minimum, in alignment with the Transparency Pledge standard.[16] The section below captures what RBIs have done or committed to do through November 2019, reflecting responses and updates from RBIs. All RBI responses are available in full in Annex III online.[17] The coalition will closely monitor whether RBIs introduce, implement, and enforce supply chain requirements for their members.

Significant Progress

The US-based Fair Labor Association (FLA) recently became the first industry-backed RBI to take a strong step forward on this issue. In February 2019 its board voted in favor of supply chain transparency and adopted a more detailed implementation plan in October 2019.[18]

Among other things, the FLA has required brands and retailers to publish factory lists that are aligned with the Transparency Pledge standard and in machine-readable formats, giving companies time till March 31, 2022 to comply.[19] The FLA says it will begin monitoring and enforcing this requirement thereafter.[20] According to the FLA, brands and retailers that fail to comply may be subject to escalation and special review by the FLA Board of Directors, and can ultimately have their FLA affiliation status revoked for continued non-compliance.[21] The FLA estimates that it has over 50 brands and retailers among its affiliates.[22]

Some Progress

The Dutch Agreement on Sustainable Garments and Textiles (AGT), a Netherlands-based multi-stakeholder initiative, whose corporate members comprise of Dutch brands, has been publishing factory information in aggregate form since 2017, without indicating precisely which brands are manufacturing in which factories.[23]

While such an approach to members’ supply chain transparency can risk undercutting corporate accountability, in the case of the AGT, a number of its members have also opted to publicly disclose their individual supply chains. The AGT estimated that over 85 percent of unique production locations (about 4,200 factories) in its aggregated list would also be separately disclosed by AGT member brands committed to aligning with the full pledge.[24] In November 2019, AGT members Dare to Be, HEMA, Kings of Indigo, Kuyichi, Okimono, Schijvens, and We Fashion, publicly committed to being in full alignment with the pledge standard.[25]

In response to the coalition’s letter, the AGT did not make changes to its membership criteria. But representatives wrote that they incorporated all five Transparency Pledge elements into an internal reporting format that members are encouraged to use.[26] The AGT also included questions in their assessment framework about commitment to the Transparency Pledge standard, rewarding extra points to companies that were in line with it.[27]

Further, the AGT requires those companies that are in their third year of membership to disclose their supplier factories beyond tier-1 to the secretariat. All corporate members are required to submit supplier factory information, regardless of a member’s size or whether they used buying agents.[28]

Notably, the AGT provides the Open Apparel Registry (OAR) details of all factories disclosed to its secretariat by its corporate members.[29]

The Open Apparel Registry has a database of global garment factory information, collating disparate factory lists into one central, open-source map that is publicly available, searchable, and free of cost, enabling workers and others easy and quicker access to information.[30]

Little Progress

The UK Ethical Trading Initiative (ETI) appears to have taken a small step in the right direction. But unlike the FLA the ETI appears to be considering tier-1 supply chain disclosure as a requirement for only its upper levels of membership.[31] Unlike the AGT, the ETI does not make publicly available even an aggregate list of production locations of all its members in a machine-readable format.

In August 2018, the ETI drew the coalition’s attention to their membership from different sectors. They noted that their members include both suppliers and retailers. They argued that, “[t]he work we are doing to drive greater transparency needs to consider all types of members and the sectors [in which] they operate.”[32]

The coalition does not believe these are barriers to advancing public disclosure as membership requirements where there is political will to do so. The FLA has retailers and suppliers, as well as companies from different sectors, among its members and has introduced sector-specific membership requirements for its members from the apparel industry.[33] The approach taken by the Organization for Economic Cooperation and Development (OECD), an intergovernmental body, is a useful model. The OECD has issued general guidance for companies to conduct human rights due diligence supplemented by sector-specific guidance. The ETI could aim for a smart mix of general and sector-specific requirements on transparency, aligned with the Transparency Pledge standard, and going beyond tier-1.

The ETI provided an extract of its internal reporting framework. This showed that the ETI asked members classified as achievers to internally report whether the “company publicly communicates supplier list information” and leaders to internally report whether “the company publicly communicates supplier list information beyond tier-1.”[34]

In July 2019, the ETI informed its members about a June 2019 board decision. According to this internal communication to its corporate members, the ETI board considered six transparency recommendations and “agreed the recommendation for a requirement that future leadership status [the highest ETI membership ranking] will be dependent on members publishing at least their Tier 1 supply chain information.”[35] The board further discussed whether to “expect leaders to publish information beyond Tier 1, whilst at the same time, requiring those on achiever status to publish information on at least their Tier 1 supply chain partners.”[36] The “board accepted all 6 [transparency recommendations] in principle, acknowledging that a few of the questions raised need further discussion and consultation.”[37] A final proposal was expected to be discussed in an October 2019 board meeting, and presented to all its corporate members in November 2019.[38]

In late October, the ETI stated that their transparency recommendations would be implemented from October 2020 and spanned three areas: “ETI’s own transparency; ETI’s transparency about its members; and ETI members’ own transparency.”[39] At this writing, the ETI declined to provide other details.

The ETI revealed that there are 4 leaders and 11 achievers among its corporate members in the apparel and footwear industry.[40] However, the ETI did not reveal their names or indicate how their transparency practices would be advanced by its board decisions.[41] Without having this information, the coalition is unable to assess the potential impact of ETI’s decisions for its corporate members in the apparel industry.

The ETI did not outline any plans to either cooperate with the Open Apparel Registry or require the machine-readability of information its members already disclose or will disclose in the future.

The Fair Wear Foundation (FWF), another Netherlands-based multi-stakeholder initiative, responded in July 2018 that “the FWF transparency policy will be effective as of early 2019, including the publication of factory data aligned with the Transparency Pledge.” Subsequently it clarified in October and November 2019 that it would make available on its website a searchable database of manufacturing units that its corporate members disclose to the FWF secretariat.[42] The searchable database would reveal data as required in the Transparency Pledge standard and is expected to be launched in the first quarter of 2020.[43]

The FWF emphasized “the relevance of transparency to improve access to remedy” and said its “aggregated publication of production locations sourcing to FWF members will therefore provide an online possibility for workers, activists, unions and others acting on behalf of workers to express concerns or submit complaints.”[44]

It outlined plans to also make available a standalone list of information about all “disclosed factories” of FWF corporate members.[45] FWF said that its grievance redress mechanism will be “further strengthened by sharing aggregated lists per country with local stakeholders like trade unions and labour rights NGOs.”[46]

However, it also wrote that it would allow its corporate members to opt out of having information about their supplier factories appear in the searchable database and the standalone aggregate list. The FWF outlined plans to publicly name brands that opted out of having their factories appear in the search database and give them lower scores on the FWF Brand Performance Check.[47] The current FWF Brand Performance Check only gives a maximum of two points for supply chain disclosure, lacking significant influence within the overall scoring. Further, FWF has not made public disclosure of supply chain information a condition for “leader status” within its scoring systems.[48] As of late November 2019, the FWF estimated that a “vast majority” of FWF corporate members’ supplier factories would appear in its public database, but did not provide precise information.[49]

Despite FWF’s strong commitment to workers’ access to remedy, its failure to combine membership requirements with supply chain transparency risks reducing the effectiveness of FWF’s grievance mechanism. This is especially because FWF allows its members to opt out of publishing information.

At this writing, it is unclear whether FWF will make its aggregate factory list available to the Open Apparel Registry.

Zero Progress

At this writing, amfori, the German Partnership for Sustainable Textiles (PST), and the Sustainable Apparel Coalition (SAC) have not made any commitments to drive their corporate members’ practices with regard to supply chain transparency by linking them to their membership criteria or scoring systems.[50] Even if internal scoring systems are maintained, they did not provide information about them, nor are they publicized for consumers and others to know how their corporate members score, including on supply chain transparency. Further, they did not give information suggesting that such scoring systems, if they exist, have implications for membership or membership status, with significant disincentives for corporate members who consistently choose not to publicly disclose their supply chains. In an online Annex, the coalition has attempted to identify members of amfori, PST, and the SAC that are transparent and non-transparent.[51]

amfori

amfori noted that its “[m]embers—multinational companies, SMEs [small and medium enterprises] and business associations—come from 44 countries with different legal systems and regulatory requirements”[52] and contend that while the coalition’s approach “is well-intentioned and an important contribution to our joint objective, [it] is not sufficiently reflecting the complex needs of our organisation and membership.”[53] The FLA, however, whose affiliates in the apparel industry are headquartered in 17 countries, including Japan, Germany, New Zealand, Canada, and the US, committed to implement minimum membership requirements that were pledge-aligned.

Despite amfori’s professed interest in advancing supply chain transparency, it was not able to provide information that demonstrates that it was consistently tracking this information internally. For example, in September 2018, amfori wrote that “it is highly encouraging that, like us, your group is very attentive [emphasis added] to the issue of supply chain transparency and is seeking ways and means to increase visibility into manufacturing supply chains.”[54] It also said that “[s]upply chain transparency is a key strategic priority for 2019 and the years to come,” and explained that its aim was to “lift the discussion to a higher level…to take specific measures across the association to ensure further progress and even more tangible outcome.”[55]

Ten months into making supply chain transparency a “strategic priority,” in response to an October 2019 information request asking amfori to provide a list of all member companies that sell apparel or footwear products, identifying the ones that publicly disclose at least tier-1 names and addresses, amfori furnished partial information.

amfori provided a list of 570 “textile members” of which 468 were small and medium enterprises (based on turnover only).[56] It clarified: “We also have 719 members in the general merchandise category (including or excluding food) some of which also sell textiles but are not included in the [570] list, as we do not have a way of filtering this information.”[57] amfori did not identify which of its members publicly disclosed their tier-1 factory lists.[58]

German Partnership for Sustainable Textiles (PST)

The PST formed a working group to explore how they could advance supply chain transparency. The working group was expected to take “a multistakeholder and membership-based approach… to come up with a comprehensive concept [for transparency]” and suggest actions.[59]

By October 2019, the PST conducted an internal survey among 75 corporate members asking whether they were willing to publish supply chain information. The PST said the results were not public but shared a summary. Of the 75 companies that were surveyed, 62 responded. Of the 62 that responded, 17 companies said they were willing to publicly disclose supply chain information; the remaining survey participants were not willing to disclose altogether (26 companies) or offered to disclose only internally within the PST (19 companies).[60] In effect, only 17 of the 62 respondents (27 percent of respondents) were willing to publicly disclose supply chain data.

Because a vast majority of PST member companies were unwilling to publish data regarding their supply chains, the PST said they continued to encourage it as a “recommended goal” that was voluntary. The PST was in negotiations with the Open Apparel Registry.

Sustainable Apparel Coalition (SAC)

The SAC wrote that “transparency will only be effective if everybody speaks a common language,”[61] and explained how over the last 10 years they had worked with their members “to bring this common language and measurement standard to the industry: the Higg Index [a sustainability measurement toolkit developed by the SAC].”[62]

The SAC also stated that because they were a membership organization, processes to review and adopt transparency requirements needed to follow “clear rules of engagement.”[63] In July 2018, the SAC was “in a process of internal conversation with… members to frame what those [transparency] requirements could be,” which the “SAC Board of Directors would then validate.”[64]

In September 2019, the coalition urged the SAC board to call for a special meeting to make a decision regarding their members’ supply chain transparency. The coalition emphasized that the SAC’s Brand and Retail module, Higg Index transparency, and supply chain transparency served different purposes and can run in parallel. At this writing, the SAC has not introduced even basic supply chain transparency requirements for its members.[65]

The SAC did not outline any plans for cooperation with the Open Apparel Registry.

Alleged Barriers to Supply Chain Transparency

In 2017, the coalition responded to the main arguments proffered by companies that resist transparency concerning their supplier factories.[66] These arguments included a competitive disadvantage from disclosing supplier factories and anti-competition laws preventing greater transparency. The growing number of apparel and footwear companies that publish lists of their supplier factories underscores that competitive disadvantage and anti-competition laws have not been barriers at all.

Two further issues raised with the coalition about purported barriers to supply chain transparency concern buying agents or intermediaries, and small and medium-size enterprises (SMEs). For example, the German Partnership for Sustainable Textiles (PST) has raised both these concerns. The PST wrote that they found that smaller companies were reluctant to publish supply chain information because these companies feared that by naming their suppliers, “they might lose reliable and long-term business partners to larger competitors.”[67] The PST also wrote that agents or business partners to larger brands feared that disclosing suppliers may lead “brands to eventually choose to start direct business relations with them.”[68]

Indirect Sourcing

Many global brands use buying agents or other intermediaries who identify and negotiate with suppliers on a brand’s behalf and source its products. These intermediaries may or may not disclose the production sites where a brand’s products are being manufactured. But brands that have zero visibility over their production sites expose themselves to heightened human rights risks. Some contend that if intermediaries disclose the production sites to a brand, it risks having the brand directly place orders with the factory, permitting them to cut out the buying agent. However, brands and retailers that use indirect sourcing for their own-brand products disclose the supplier factories. These include ALDI South, Clarks, Kings of Indigo, Lidl, and Schijvens.[69] In order for a brand to bolster its human rights due diligence, it should do business only with those intermediaries who are willing to disclose to the brand the production sites they use, which brands can then publish online.

Small and Medium Size Enterprises (SMEs)

As noted above, some companies and industry-backed groups attempt to justify their unwillingness to disclose their supplier factories on the grounds that they, or some of their member firms, are SMEs.[70]

They contend that such firms are either less able to obtain information from their suppliers concerning where their products are manufactured (ostensibly because the relatively smaller sizes of their orders gives SMEs less influence with their suppliers), or face greater competitive risks from disclosure (because larger firms presumably can offer the suppliers of SMEs more competitive pricing and larger orders due to economies of scale).

However, the first claim—that SMEs have less ability to obtain information concerning production sites from suppliers—does not constitute a justification for SMEs refusing to publicly disclose supplier factory information that they are able to obtain. And the second, that SMEs face greater competitive risk from supply chain disclosure, is not backed up by verifiable evidence. There is, to our knowledge, no published research, showing either quantitatively or anecdotally, that SMEs that disclosed their supply chains are more likely to face negative impacts in their sourcing.

Evidence from one of largest publicly available sources of supply chain data suggests these purported concerns are overblown. The Worker Rights Consortium (WRC) has for nearly two decades published an online database of the supplier factories of companies licensed by WRC’s affiliate universities and colleges in the US and Canada to market products bearing these schools’ names and insignia.[71] There are currently more than 150 affiliated universities and colleges and more than 2,500 companies that are contractually required by the WRC’s affiliate institutions to disclose their supplier factories.[72]

Although the largest of these companies are multi-billion-dollar athletic apparel brands, such as Nike, Adidas, and Under Armour, the vast majority are much smaller companies, including many “mom-and-pops” (i.e. small family-owned firms), whose revenues can be less than US$300,000 per year.[73]

In November 2019, SMEs like Dare to Be, Kings of Indigo Kuyichi, and Schijvens committed to the Transparency Pledge standard.[74]

Online Retailers: Amazon, ASOS, and Zalando

Consumers are increasingly resorting to shopping online rather than from bricks-and-mortar retail locations. For example, Just-Style, a leading apparel industry magazine reported that in 2018 UK online spending was projected to reach US$74.9 billion.[75] The US Department of Commerce reported that US retail e-commerce sales for the second quarter of 2019 was $146.2 billion, accounting for about 10 percent of all retail sales.[76]

Given the growing prominence of online retail in the apparel industry, in 2018 the coalition wrote to Amazon and Zalando, two prominent online retailers who also source own-brand apparel. The coalition urged Amazon and Zalando to publish the details of factories that produce their branded products, in alignment with the Transparency Pledge standard. In 2016, the coalition had approached ASOS, the UK-based online retailer with own brands, urging it to publicly disclose its supplier factories list, and it did so.[77]

Zalando responded positively, with a commitment to publicly disclose its own-label supplier factories by the end of 2019.[78] In November 2019, Amazon published a list of facilities that produce Amazon-branded apparel, consumer electronics, and home goods products,[79] shifting from its August 2018 response.[80]

Amazon’s public disclosure, and whether the company will come into alignment with the Transparency Pledge standard, assume special significance because of its size. One market analyst estimated that Amazon will account for about 37.7 percent of US e-commerce sales (across all product categories) in 2019.[81] Amazon is primarily known as an e-retailer selling third-party goods, but in recent years it has moved to develop and sell its own-brand products, including Amazon’s own apparel lines. Since 2017, according to one estimate, Amazon produced seventy different own-brand products, many of which are apparel.[82] At least eight of these are well-known: Amazon Essentials, Buttoned Down, Ella Moon, Goodthreads, Lark & Ro, Mae, Paris Sunday, and Scout +.[83]

Company Transparency Practices: A 2019 Update

Since 2016, when the coalition first developed the Transparency Pledge and began outreach, numerous companies have committed to and implemented the Pledge standard. The status of the commitments and implementation, and other newer developments are captured in Annex II of the report (available online).[84] Numerous companies have deepened supply chain transparency to go beyond manufacturing units.

As of late November 2019, of the 72 companies that the coalition first reached out to in 2016:[85]

- 22 companies are either fully aligned or committed to aligning with the Transparency Pledge standard. These are: adidas, ASICS, ASOS, Benetton, C&A, Clarks, Cotton On, Esprit, G-Star RAW, H&M, Hanesbrands, Levi Strauss, Lindex, Mountain Equipment Co-op, New Balance, New Look, Next, Nike, Patagonia, Pentland Brands, PVH Corporation, and VF Corporation;

- 29 companies publish at least the names and street addresses of their supplier factories, but still fall short of the pledge standard.[86]

- 18 companies have yet to publicly disclose supply chain information. These are: American Eagle Outfitters, Armani, Canadian Tire, Carrefour, Carter’s, Decathlon, Dicks’ Sporting Goods, Foot Locker, Forever 21, Inditex, KiK, Mango, Ralph Lauren, River Island, Sports Direct, The Children’s Place, Urban Outfitters, and Walmart.[87] Two companies—Abercrombie & Fitch and Loblaws—disclose factory name and country only, without providing the street address. Desigual has committed to publishing factory names by country in 2020.[88]

In addition, as of November 2019, 17 other companies that are not among the 72 counted above are already publishing their supplier factories list in full alignment with the Transparency Pledge standard or have committed to do so by 2020. These are: Alchemist, Dare to Be, Eileen Fisher, Fanatics, Fruit of the Loom, HEMA, KappAhl, Kings of Indigo, Kontoor Brands, Kuyichi, Lacoste, Lululemon Athletica, Okimono, Schijvens, Toms, We Fashion, and Zeeman.[89] Gildan has begun disclosing and just falls short of the pledge standard.[90]

|

Moving Beyond the Transparency Pledge Many companies that are either already fully aligned or in close alignment with the Transparency Pledge standard publicly disclose a range of other details about their factories and other parts of their supply chain.[91] A snapshot of good practices, which is not comprehensive, is captured below. Examples of additional data about supplier factories now disclosed by some brands:

Going beyond tier-1 factories:

|

Embracing Technology: Open Data Standard

The ultimate objective of publishing lists of supplier factories is to make them useful for workers, companies, and civil society. Making published lists of supplier factories machine-readable and facilitating their compilation into searchable and accessible online databases is key. As discussed above, workers, their representatives, advocates and nongovernmental organizations can use factory-level information to swiftly alert brands to labor abuses at an early stage. From a brand perspective, having multiple channels to identify and report labor abuses adds value to other elements of due diligence on compliance with human rights responsibilities.

To achieve these twin goals, workers, their representatives, and civil society groups should be able to search and use factory information easily. With growing supply chain transparency, increasing amounts of factory-level information are publicly available in different formats. This makes it harder and more time-consuming to search manually. Several issues currently undercut the usability of published supply chain information. These include:

- Published lists of supplier factories on brands’ websites in formats that are not machine-readable (HTML, PDF files, and maps);

- Brands generally only provide their current supplier factories’ lists; but historical data is important to establish when a brand started or stopped using a supplier factory;

- Lists of supplier factories are often hard to find on brand or retailer websites and are disclosed without explicit permission for reuse; and

- Different brands sometimes spell the names of factories differently or there are small mismatches in addresses, making it harder for workers and brands themselves to use the information in the absence of a unique factory ID.

To harness the full human rights due diligence potential of published factory information, with maximum efficiency and minimize time wasted, the coalition strongly urges companies to align their published factory lists with the Open Data Standard for the Apparel Sector (ODSAS). ODSAS allows the factory information to be machine-readable; automatically updates with newer factory disclosures; and makes the information easily searchable for workers and their representatives. Companies can embrace ODSAS with three simple steps:

- Publish a downloadable, machine-readable file at a regular common frequency in one or more of the following formats: csv, json, or xlsx;

- Publish a list of their supplier factories using a common disclosure template; and

- Ensure that pages carrying information about supplier factories use an open license (which gives permission for reuse).[92]

|

Good Practice for Formats of Disclosure |

|

Nike Nike is not only fully aligned with the Transparency Pledge standard, but also provides its supply chain data in user-friendly formats and updates it quarterly. Nike also provides a more consumer facing, interactive map of its suppliers, allowing the data from its map to be exported and downloaded as either a PDF, excel, or json file. Excel and json are machine-readable formats. Other companies including adidas, Esprit, Mountain Equipment Co-op, New Balance, Patagonia, Pentland Brands, PVH Corporation, and VF Corporation publish their information in downloadable machine-readable excel format. |

Conclusion and Recommendations

Between 2016 and 2019, supply chain transparency in the apparel industry has grown tremendously. Dozens of companies now publish the names, addresses, and other details of supplier factories. But this is only a starting point. Apparel brands and retailers that are serious about ethical supply chains can and should do more. A handful of companies have begun to disclose parts of their supply chain beyond tier-1, including mills. Supply chain transparency is powerful because it provides basic information that facilitates redress for workers’ grievances. Workers benefit from easily accessible factory and brand information and can also help brands to collaborate where they share supplier factories; companies benefit from more sources of information about their factories, bolstering their human rights monitoring. Responsible Business Initiatives (RBIs) should play an important leadership role in driving and scaling up such transparency. Finally, governments should regulate companies’ human rights due diligence responsibilities for their global supply chains and integrate transparency requirements.

Recommendations

To all companies regardless of size and business model

- Commit to and implement the Transparency Pledge in 2020 by disclosing names, addresses, and other details of supplier factories.

- Begin publicly disclosing other parts of the supply chains, including mills and farms.

- Align published factory lists with the Open Data Standard for the Apparel Sector and consider submitting the information to the Open Apparel Registry.

To all Responsible Business Initiatives (RBIs)

- Bridge the transparency gap among corporate members, regardless of size or business model, and exert leadership by making supply chain transparency a condition of membership, including membership levels.

- Introduce transparency requirements beyond tier-1 to progress toward upper levels of leadership, or to be part of the RBI board.

- Publish full survey responses that impact RBI governance, identifying clearly which members participated and how each of them responded.

- Require all supply chain information—whether published by companies or the RBI—to comply with the Open Data Standard for the Apparel Sector and consider submitting the information to the Open Apparel Registry.

- Mandatorily track which companies are transparent about their supply chains and periodically publish these lists to inform consumers, investors and broader civil society.

To all governments

- Enact laws that require and promote mandatory corporate human rights due diligence as well as non-financial reporting, for the global supply chains of companies, and integrate supply chain transparency requirements as part of such legislation.

- Amend customs-related regulations to ensure that all companies that import goods into the country are required to disclose the name and address of the manufacturer to the relevant customs authorities, and make this data publicly available.